Intra services company is the only company at the territory of the Russian Federation supported by RF president and legalized in respect of leak sealing technology at the existing equipment by the federal service for environmental, technological and nuclear supervision of the Russian Federation (Rostekhnadzor).

Advantages

Considerably reduced costs related to process equipment downtime and stoppage of production process

Considerably reduced risk of emergencies and man-made disasters

Reduced level of environmental release of hazardous substances, fewer instances of emergency oil spills (environmental safety)

Versatile and safe sealing methods

Ensuring safe operating conditions for equipment during inter-repair periods

Increased lifespan of the main stock, economy of materials

Reduced amounts of product waste and power consumption

Equipment maintainability

APPLICATION

- Flanged joints

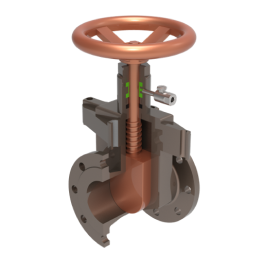

- Valve packing chambers

- Welding joints

- The body of pipeline elements and valves of various configurations

Industries

Oil and gas production

Recycling

Transportation

Metallurgy

Chemistry/

Petrochemistry

Petrochemistry

LNG

Power industry

Pulp and paper plant

TECHNIQUES

SEALING OF PIPELINE

VALVES

VALVES

SEALING WITHOUT

A CLAMP

A CLAMP

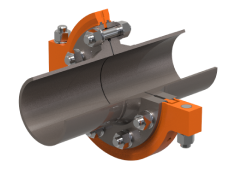

SEALING WITH

A RING CLAMP

A RING CLAMP

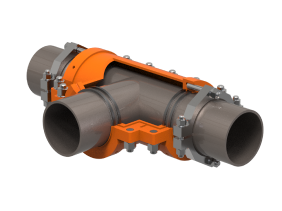

SEALING OF

A PIPELINE SECTION

A PIPELINE SECTION

PARAMETERS

Products:

Steam, water, heavy gas oil, light gas oil, gasolenes, hydrogen, ammonia, nitrogen, sulfuric acid, hydrofluoric acid.

Temperature:

from - 20 °С

to + 350 °С

from - 20 °С

to + 350 °С

Pressure:

from 0 mpa

to 100 mpa

from 0 mpa

to 100 mpa

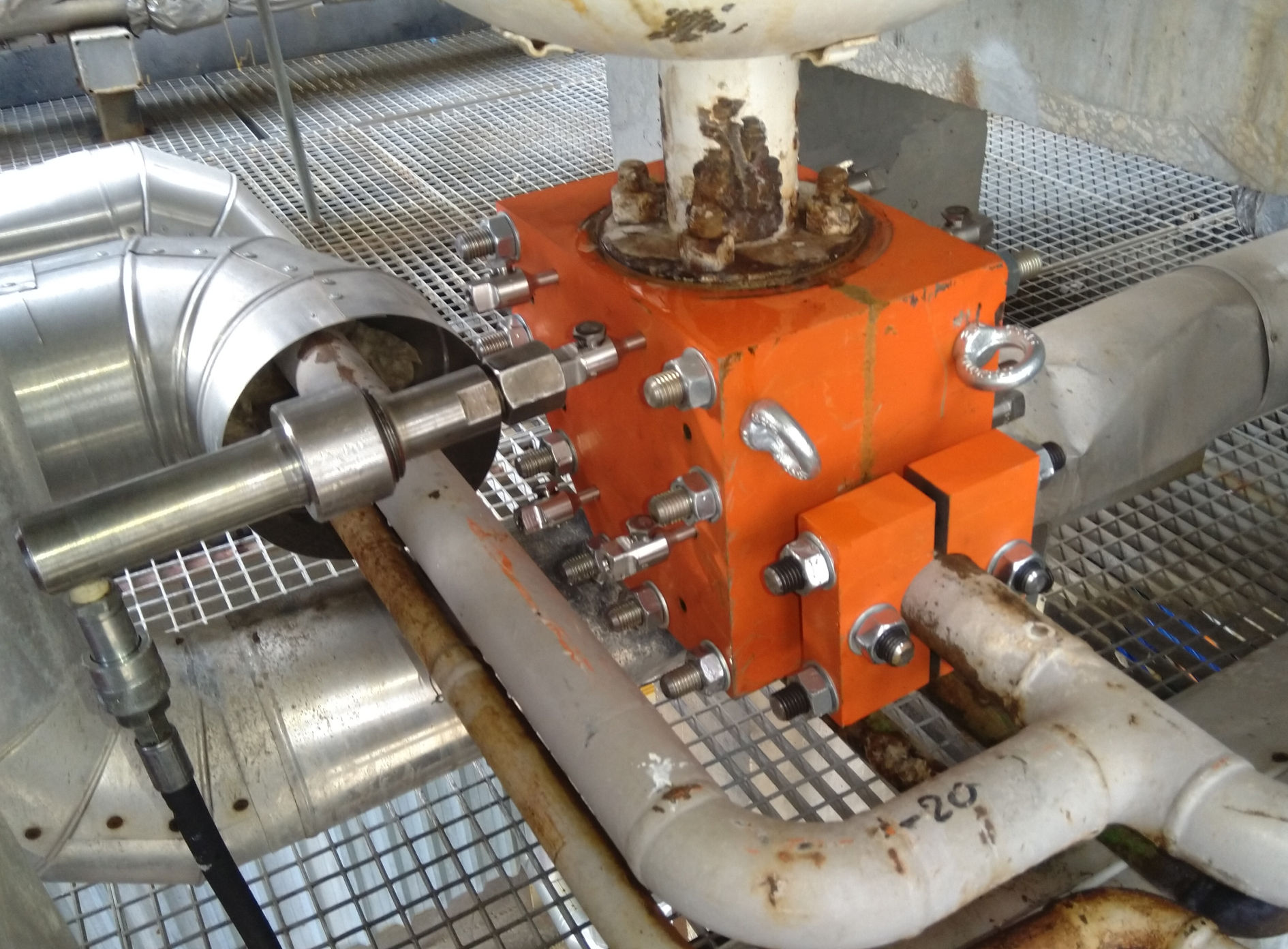

TECHNOLOGY

1 PREPARATORY STAGE

Treatment and reinforcement of the damaged part of the pipeline for subsequent work performance (replacement of fasteners, installation of ring adapters, installation of a clamp for flanged joint extra tightening).

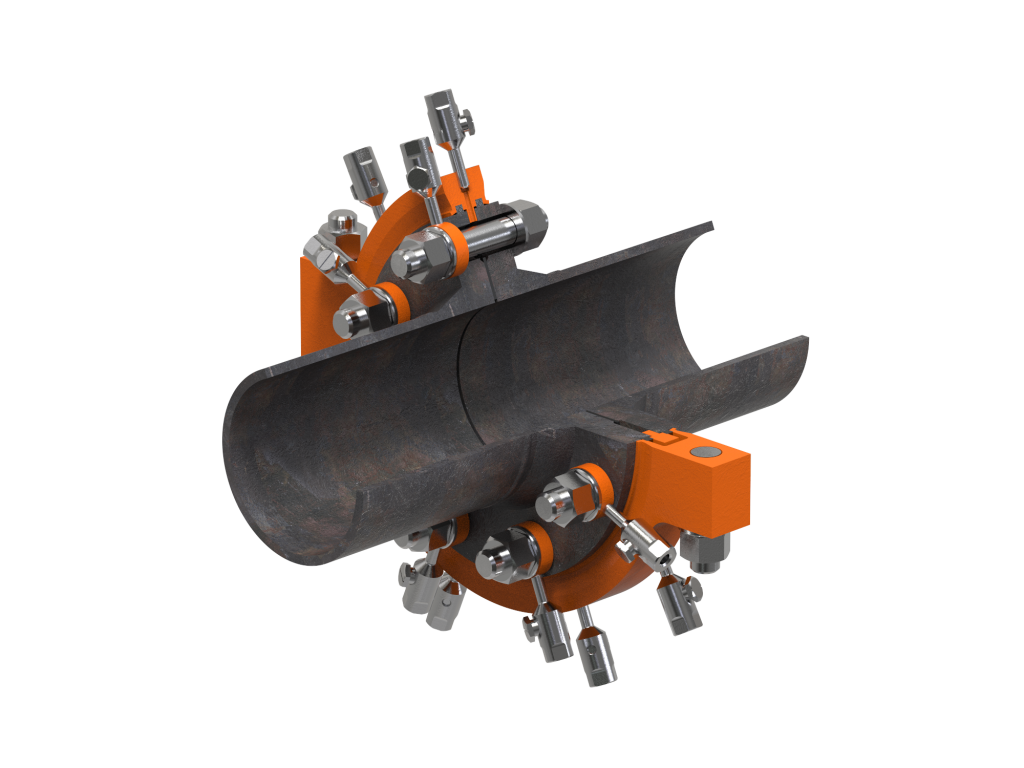

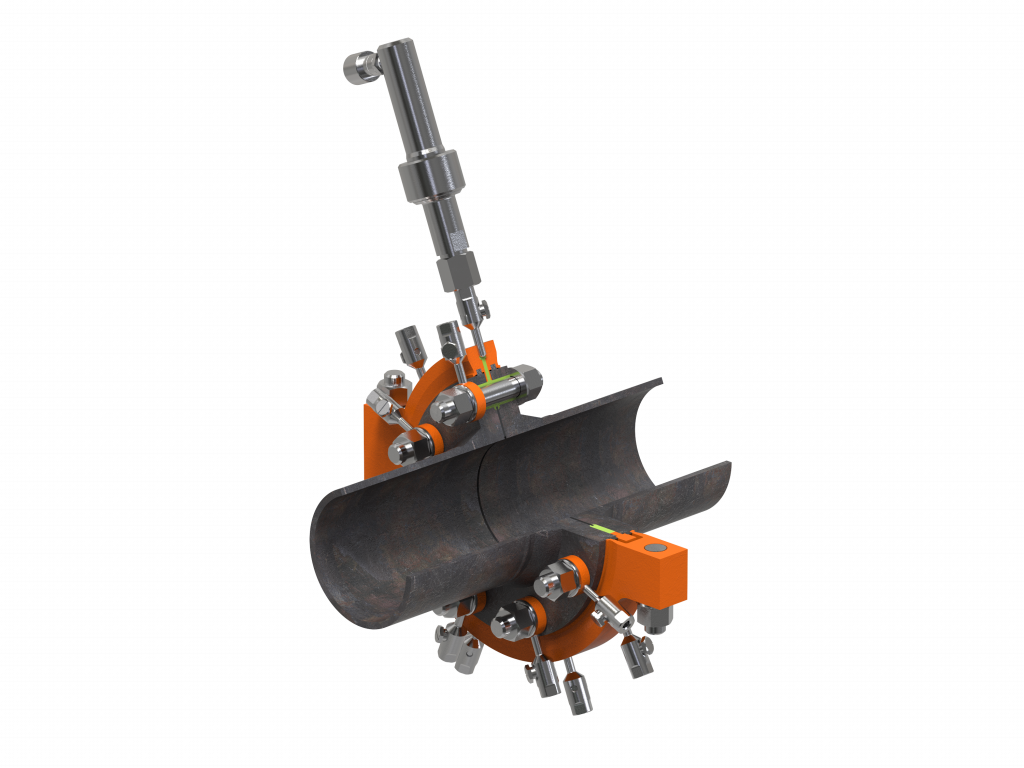

2 LEAK CONFINEMENT

Depending on the pressure of the transported medium and leak size, different confinement methods are used without changing working medium pressure and stopping the production process.

3 PREPARATION TO COMPOUND INTRODUCTION

Installation of injection adapters in the confined leakage area for subsequent filling with the compound.

4 INTRODUCTION OF A COMPOUND

Filling with compound (special rubber-based filler whose properties depend on the nature of the transported medium) by means of an injection gun.